-

Choose your category:

-

- Exploration Solutions

- Core & Well log analysis

- Geochemical Analysis and Interpretation

- Petrophysical Interpretation

- Rock Physics, Seismic QI

- Geomechanics

- Basin Analysis and Regional Studies

- Geological interpretation and Modeling

- Prospect Inventory and Risk analysis

- Drilling & Completion

- Concept Selection, Conceptual Design

- Preliminary well design and planning

- Detailed well design and planning

- Integrated Reservoir Study

- Core & Well log analysis

- Petrophysical Interpretation

- Rock Physics, Seismic QI

- Geomechanics

- Geological interpretation and Modeling

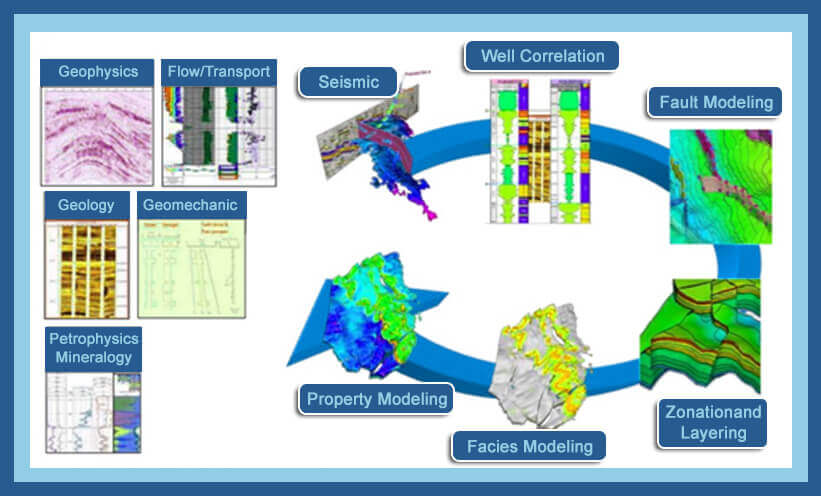

- Static Modeling

- Basic Reservoir Engineering

- Dynamic Modeling

- Uncertainty Analysis and History Matching

- Production Forecasting

- 4D Seismic

- Increased Oil Recovery

- Fast increase oil recovery Solutions

- EOR; from concept to field implementation

- Economic Studies & Risk Evaluation

- Production Engineering

- Flow Assurance

- Artificial Lift Design

- Material Selection

- Production Chemistry

- Surface Facilities

- Flow Assurance

- Process and facility engineering

- Material Selection

- Operation Assurance

- Production Chemistry

- OTS & Dynamic Simulation

Dynamic Modelling

For dynamic modeling, we combine the static model, pressure- and saturation-dependent properties, well locations and geometries, as well as the facilities layout to calculate the pressure/saturation distribution into the reservoir, and the production profiles vs. time. The entire life time of reservoir is simulated by considering different production schemes and operating conditions to maximize recovery from the reservoir.

Our dynamic modeling involves five steps:

Setting objectives

Selecting the model and approach

Upscaling the geological model by maintaining the same storage and transport properties of the reservoir rock described in detail by the “fine geological model ”

Gathering, collecting and preparing the input data

Planning the computer runs, in terms of history matching and/or performance prediction

Analyzing, interpreting and reporting the results

In order to decide which type of simulation model to select, it is very important for us to know the recovery process of the reservoir to reproduce the main reservoir drive mechanisms and the necessary accuracy of the expected results. Our expert team always gathers and checks the available information to ensure the quality of the data as it influences the level of detail to use in the model.

In NAED we are capable of working with Black oil, compositional, and thermal models to represent best drive mechanisms of a different type of reservoirs, and the selection depends on the type and behavior of the original reservoir fluids and on the predominant process controlling the reservoir production and hydrocarbon recovery.